- Home

- Custombikes

- Harley-Davidson

- Vintage

- Build a Billy

That's how our Winner Bike came into being

In Faak we had a little time to work on some ideas we had for the BBO. The public gets a chance to vote there so we had to come up with something to surprise them, to build something a bit different, something that nobody would expect us to build.

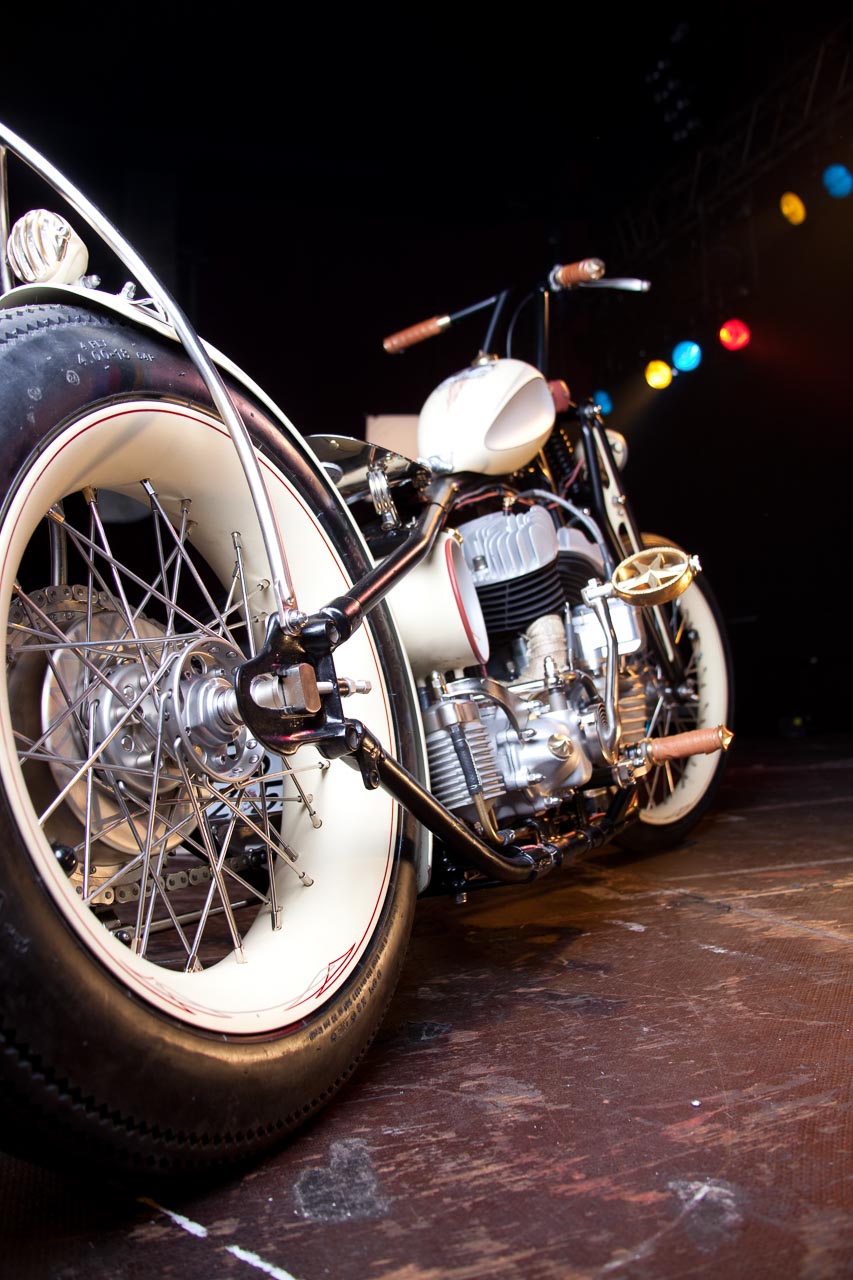

An extreme old-school bike! That would be the first one for us! But then we’d take one, that’s the real McCoy, a Flathead, nobody in Germany has ever customized one before, and we happened to have one standing around in the shop.

As we came back from Faak, we took the poor old thing apart, and used some used parts to define the style we wanted; extremely narrow, with the tank high up in the air, so the engine would be clearly visible, a narrow T or Z handlebar, tall and skinny wheels, like we think a chopper for a Rock-a-Billy should look.

Our tires of choice would, of course, be the Firestones, with their Zig-Zag profile. The rims we used are similar in style to the ones used on the Softail Custom, or the Deluxe, they’re not old-school at all, just look that way. The only problem was, that these are were only available in a 16” or 21” size, so we had to machine the rear rim from a rather large piece of billet alloy, we choose the 4,5X18” size.

Once we decided which wheel size we’re going to use, we took the bike completely apart, and sandblasted the frame a fork. Much to our horror, the battle-scars of 67 years on the road appeared .Basically what was left of the frame and fork was ripe to be junked, as some bodged-up accident repairs really left their mark on the parts.

So we put the frame in our frame-jig, and exchanged all the tubes between the cast parts. The good thing about this exercise was, that we had a chance to narrow the section of the frame around the seat, and cover the parts around the seat-post. We put in a lot of extra effort to work on the frame, just as builders would’ve done in days long gone.

We made the peanut tank even narrower, by making the sides curved-in. The side mounted tank fueltap were closed, and refitted in a different place.

The oiltank had to be made from scratch, also with curved sides to match the gastank, and sloped, to fit the frame.

As we put the bike together again, it turned out the front fork now was too wide for the bike, so we bought a DKW fork on Ebay.

This fork however was a little unstable for this bike, so we only used the mechanical suspension parts, and made the rest ourselves.

- Base Harley-Davidson UL 1941

- Engine Flat Head SV 74

- Ignition Magneto

- Carburetor SU 1 ¾”

- Intake Thunderbike Billy Special

- Muffler Thunderbike Billy Special

- Handlebar Thunderbike Billy Special

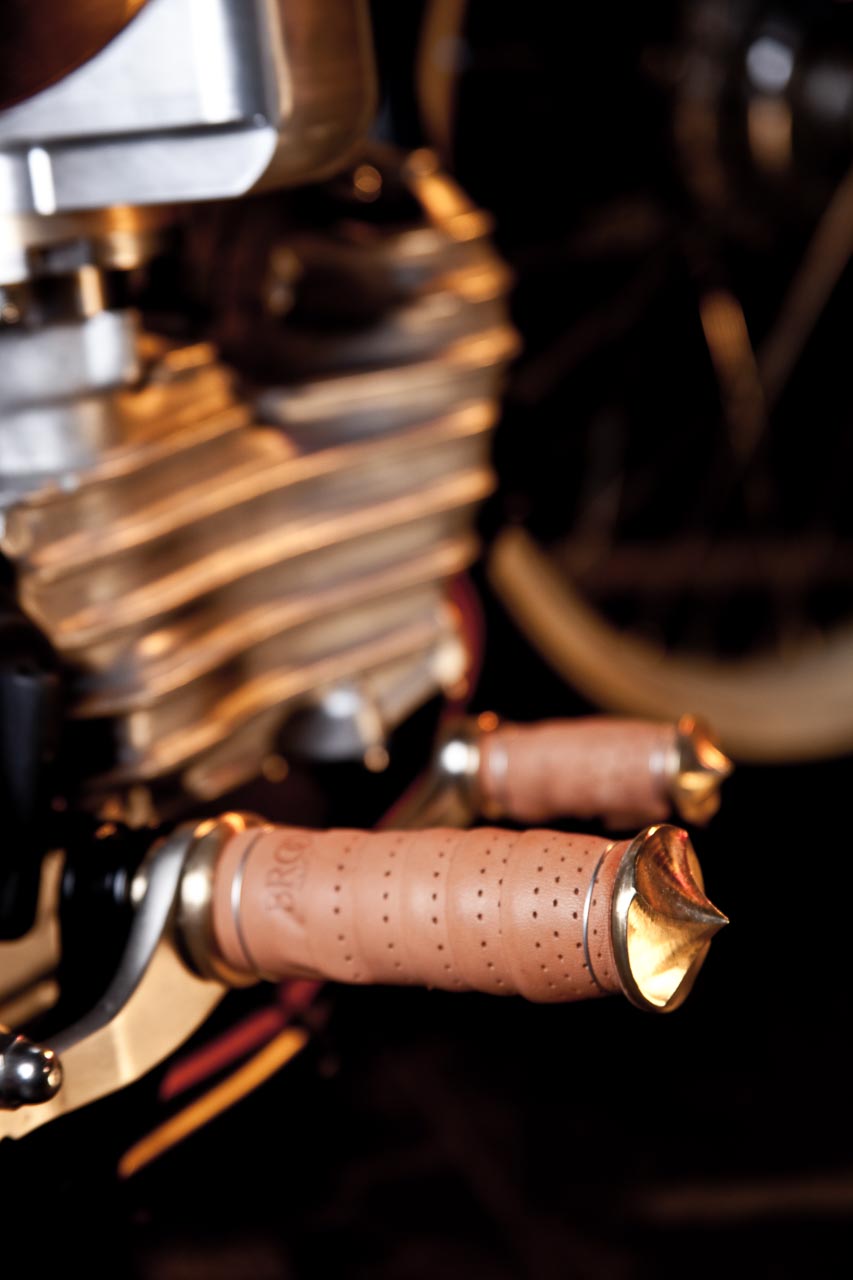

- Grips Thunderbike Billy Special

- Footpegs Thunderbike Billy Special

- Fuel Tank Thunderbike Billy Special

- Oiltank Thunderbike Billy Special

- Rear Fender Thunderbike Billy Special

- Sissybar Thunderbike Billy Special

- Electric Thunderbike Billy Special

- Seat Custom Leather

- Kicker Pedal Crime Scene Choppers

- Taillight Crime Scene Choppers

- Front End DKW

- Front Rim Softail Custom 2.15×21

- Front Tire Avon Speedmaster 3×21

- Rear Rim Thunderbike Billy Special 4.5×18

- Rear Tire Firestone 4×18

- Brakes Drumbrakes

- Painting by Ingo Kruse / Kruse Design

You can find Thunderbike Parts and original Harley-Davidson Parts in our online shop.

As Ingo put on the basecoat I took some pictures and send them to Armin Dobstetter of Custom Leathers. I told him about the BBO, and asked him to come up with a seat, we gave him carte blanche. The first time we saw the seat was at the BBO, truly a piece of art!

Meanwhile, back at the shop, the ongoing process of the build went on: SU-carburetor, magneto, nuts and bolt, skulls, bullet-fuel tap…etc.

And nothing in chrome! Whenever parts were delivered in chrome, we dechromed them and had them nickel plated.

Once we were on stage we:

Assembled the gearbox, spoked the wheels, fitted the tires, adjusted the wheel bearings, bent the oil-lines from brass piping and put them on the bike, bent, welded and modified the exhaust pipes and exhaust brackets, made cables and assembled the chain and sprockets. A lot of spacers were made on a little lathe during the BBO, as we put the bike together. And we didn’t even have to ask Ingo to show us what he can do, so while we were building, he painted the mural and pinstripes on the tank. Like the rest of the paint job: simply horny!

Last, but not least: a big thank you to the Toolman, who provided us with everything we needed, and who even got us the little lathe, shortly before we begun!